Introduction

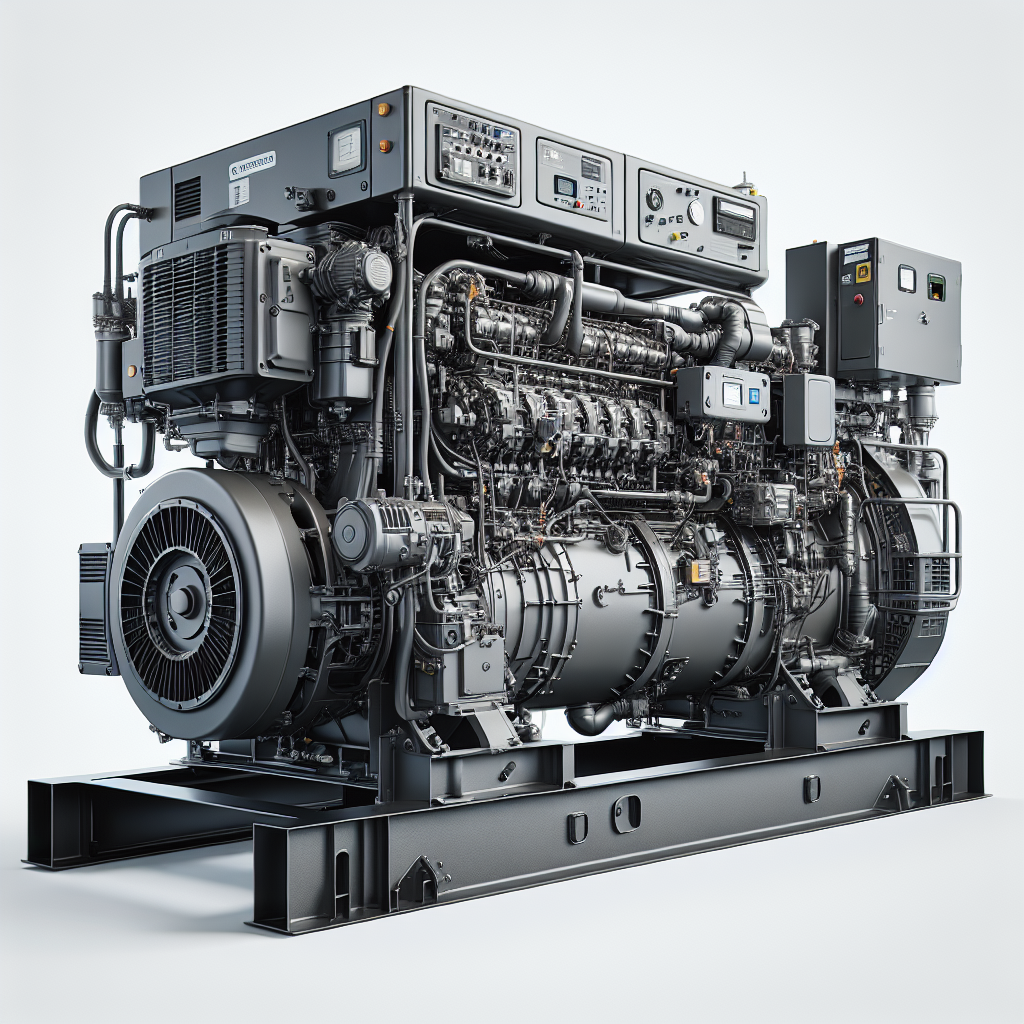

In industrial settings, a reliable power supply is crucial for ensuring uninterrupted operations. Diesel generators play a vital role in providing backup power during outages or emergencies. To ensure the reliability and performance of a diesel generator before it is installed on-site, factory acceptance testing (FAT) is conducted. This article will explore the importance of diesel generators in industrial applications, the process of factory acceptance testing, and the key considerations for selecting and testing a diesel generator for FAT.

Importance of Diesel Generators in Industrial Applications

Diesel generators are commonly used in industrial settings due to their reliability, efficiency, and cost-effectiveness. In manufacturing plants, warehouses, data centers, and other industrial facilities, a continuous power supply is essential for maintaining operations and preventing costly downtime. Diesel generators are designed to provide backup power during grid outages, ensuring that critical equipment and systems remain operational.

75kw diesel generator for remote engineering projects of the key advantages of diesel generators is their ability to produce a large amount of power quickly and efficiently. Diesel engines are known for their high power density, making them well-suited for heavy-duty applications in industrial settings. Additionally, diesel fuel is widely available and easier to store than other fuels, making diesel generators a convenient choice for backup power generation.

In industrial applications where power quality is critical, diesel generators are often preferred for their ability to provide stable and reliable power output. The voltage and frequency regulation of diesel generators are typically better than other types of generators, making them suitable for powering sensitive equipment such as computers, servers, and other electronic devices.

Overall, diesel generators offer a reliable and cost-effective solution for providing backup power in industrial settings. However, to ensure that a diesel generator meets the specified requirements and standards, factory acceptance testing is essential.

Factory Acceptance Testing (FAT) of Diesel Generators

Factory acceptance testing (FAT) is a critical step in the procurement and installation of a diesel generator for industrial applications. FAT is conducted at the manufacturer's facility to verify that the generator meets the specified performance criteria, design standards, and regulatory requirements before it is delivered to the customer's site.

The primary objectives of FAT for a diesel generator include:

1. Verifying that the generator meets the technical specifications outlined in the purchase order

2. Ensuring that the generator is designed, manufactured, and tested in accordance with industry standards and regulations

3. Identifying any defects, deficiencies, or non-conformities that need to be addressed before installation

4. Demonstrating the performance and reliability of the generator under load conditions

5. Providing the customer with confidence in the quality and functionality of the generator before it is commissioned on-site

The FAT process typically involves a series of tests and inspections that evaluate various aspects of the diesel generator, including:

1. Mechanical integrity: Checking the overall construction, alignment, and structural integrity of the generator set, including the engine, alternator, control panel, and other components.

2. Electrical performance: Testing the voltage regulation, frequency stability, and power output of the generator under different load conditions to ensure compliance with the specified requirements.

3. Control system functionality: Verifying the operation of the control system, including start-up, shutdown, load sharing, synchronization, and protection functions.

4. Environmental testing: Subjecting the generator to environmental conditions such as temperature, humidity, and vibration to assess its performance in harsh operating environments.

5. Safety and compliance: Ensuring that the generator complies with relevant safety standards, codes, and regulations, including electrical safety, emissions, and noise levels.

Key Considerations for Selecting and Testing a Diesel Generator for FAT

When selecting a diesel generator for factory acceptance testing, several key considerations should be taken into account to ensure that the generator meets the requirements of the application and performs reliably in industrial settings. Some of the important factors to consider include:

1. Power rating and load capacity: The power rating of the diesel generator should be matched to the specific power requirements of the industrial facility. The generator should have sufficient capacity to handle the peak load and provide backup power for critical equipment and systems.

2. Fuel efficiency and runtime: Diesel generators are known for their fuel efficiency and long runtime, which are important considerations for industrial applications where extended outages may occur. The generator should be able to operate continuously for an extended period without refueling.

3. Emissions and environmental impact: Diesel generators are required to comply with emissions regulations to minimize their environmental impact. The generator should be equipped with emission control systems and meet the emission limits set by regulatory authorities.

4. Maintenance and serviceability: The ease of maintenance and serviceability of the diesel generator is important for ensuring long-term reliability and performance. The generator should be designed for easy access to components and regular maintenance tasks.

5. Remote monitoring and control: In industrial settings, remote monitoring and control capabilities are essential for managing the generator and monitoring its performance from a central location. The generator should be equipped with advanced control systems and communication interfaces for remote operation.

6. Testing and validation: Before conducting factory acceptance testing, the manufacturer should perform rigorous testing and validation of the diesel generator to ensure that it meets the specified requirements. The generator should undergo performance testing, load testing, and reliability testing to verify its operation under different conditions.

7. Documentation and certification: The manufacturer should provide comprehensive documentation, including test reports, operation manuals, and certification of compliance with relevant standards. The documentation should be reviewed and approved by the customer before the generator is accepted for delivery.

Conclusion

Diesel generators play a crucial role in providing backup power for industrial applications, ensuring uninterrupted operations during grid outages or emergencies. To ensure the reliability and performance of a diesel generator before it is installed on-site, factory acceptance testing (FAT) is conducted at the manufacturer's facility. FAT involves a series of tests and inspections to verify that the generator meets the specified requirements and standards.

By selecting and testing a diesel generator for FAT based on key considerations such as power rating, fuel efficiency, emissions compliance, maintenance, remote monitoring, testing, and documentation, industrial facilities can ensure that the generator will perform reliably and efficiently in their operations. Ultimately, factory acceptance testing of diesel generators is essential for ensuring the quality and functionality of the generator before it is commissioned on-site, providing customers with confidence in their backup power supply system.